When gas prices crept up to $4/gallon in the United States (it’s happened before, it will happen again) we started seeing a lot of questions about the oil supply, driven mainly by concern about what is driving the prices up. There is not room enough to adequately describe all the regional and local processes that control the price of gasoline, but there are some relatively straight-forward principles involved. We will discuss several in this and following chapters.

Q: Is the world running out of oil?

– Mark M.

A: The answer is yes and no. I thought you’d like that.

Yes, the world is running out of “sweet” crude – the easy-to-get stuff, the “low-hanging fruit” of the hydrocarbon world.

No, there is plenty of oil still left out there – surprisingly huge amounts, in fact – but it’s the hard-to-get stuff. It is more difficult to find (and therefore more expensive) and a lot more dangerous to extract, and therefore even more expensive still… but there are a LOT of unexploited hydrocarbons still out there. The April 9, 2012 issue of Time Magazine (http://content.time.com/time/magazine/0,9263,7601120409,00.html ) gives a good summary of why there is a lot of new oil coming online – yet gas prices will still inevitably go up. However, even this particular article is not complete, largely missing the more recent Fracking Revolution, and unfortunately you also need a subscription to even read it.

Sigh. These journalists – always feeling like they need to feed their families!

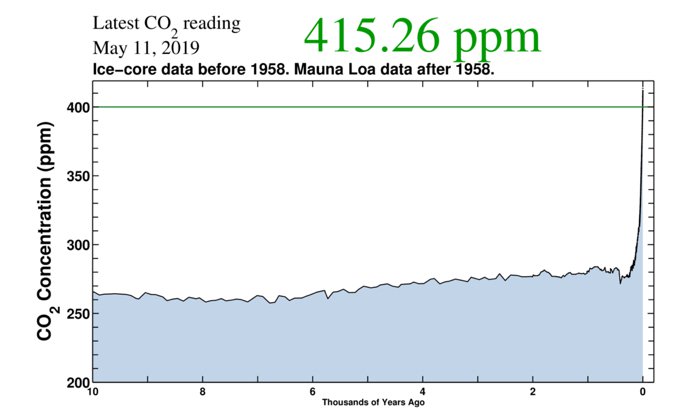

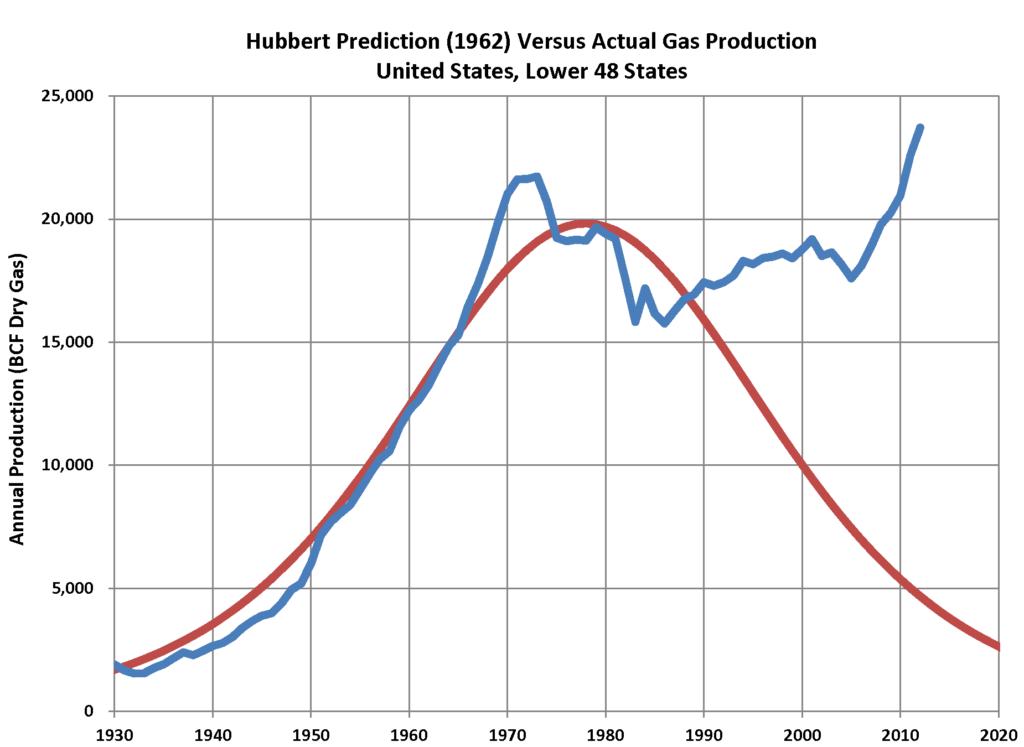

In 1956, a US Geological Survey geologist named M. King Hubbert published a paper describing the life history of an oil play (Hubbert, 1962). From discovery to full exploitation, the production of a given oil field quickly ramps up, reaches a peak… and then declines in a roughly symmetric curve as you pump most of the good stuff out. If you put together a production curve for all the major fields in the United States, it makes sense that they would all, in aggregate, behave in a similar fashion: US production would ramp up, reach a peak, and then peter out. Hubbert was the first to reason this out, and his prediction in the late 1950’s is called the Hubbert Curve.

This curve has proven remarkably accurate – at least insofar as its build up and decline shape is concerned. It has been consistently incorrect, however, as US production seems to always be greater than the Hubbert prediction. More recently, the fracking revolution has totally upended the Hubbert curve. Hubbert also had some fierce detractors, including the chief geologist (and later USGS Director, Vincent McKelvey), who all disagreed with his reasoning.

As we watch prices rising it might be tempting to either get depressed – or buy stocks in alternative energy sources. However, there were several things that this famous curve didn’t factor in, and those things include supply-and-demand laws (basic economics), geopolitics (the narrow Strait of Hormuz, for instance), and… the incredible ingenuity of the human mind. It doesn’t take a lot of smart guys, either, if there is money driving the train. Yes, Capitalism. If you have 7 billion people on a planet, it just takes a few with the vision and the determination to find a way. In most cases like this (a notable exception being everyone other than Wall Street during the Great Recession), everyone benefits.

Figure 56. The Hubbert Curve (red) and actual gas production (blue) as of 2012. Image: Plazak, Wikipedia.

For this chapter, I will only discuss enhancing production – stretching that Hubbert curve out. I worked as a young physicist for Getty Oil Company in Bakersfield, California. It was a huge improvement over fighting forest fires and washing dishes to pay for college. Getty (formerly Tidewater Oil Company) had been sitting on vast stretches of the Kern Oil Field since it had initially been exploited in the First World War era. By the time I went to work for them, the area called Oildale was an ecological ruin: the ground everywhere was reddish brown, and there was sparse, always sick vegetation. Early wells in the ’20’s and ’30’s would “blow out” as the drill reached the producing horizon (which was quite shallow, ranging from as little as just 500-900 feet, or 150-275 meters in depth), and oil would blast out all over everything until the pressure dropped. The field was originally found by following natural seeps decades before geophysical technology was developed. The Roustabouts – the guys who built and then worked the wooden derricks at the time – would rush to build a dam to save at least some of the Black Gold that came gushing out. The Kern field by the late 1960’s was well past the maximum production point. The overlying ground pressure had long since squeezed out the low-viscosity, easy stuff, and no longer squeezed anything. Pumps were producing ever-dwindling results, sometimes down to a barrel or two a day. Since the pumps ran on diesel fuel, it quickly became uneconomic to keep these running, and large parts of the field had already been shut down by the time I arrived.

But several brilliant geologists did some core-drilling, initially to see if there were places where they could put more or better pumps. They were astounded to learn that the “nearly dead” Kern Field had produced only about 15% of its entire contents since 1915! The other 85%, the black stuff that remained in the ground and showed up in those cores as sandy tar was too viscous to work its way out. In other words, it was too “gooey” for the straining pumps to move efficiently. Today we call this Heavy Crude. Some equally brilliant engineers figured out that if you could heat the stuff, the viscosity would drop, and it would flow out much more easily.

There are two problems with this:

A. You have to somehow heat it up, and then…

B. You somehow have to keep it warm or it will turn solid and clog your pipes.

There are essentially three ways to move the heavy crude sludge to the surface: water flood, steam flood and fire flood. Then move it down pipes afterwards? That’s a whole different ball-game, but it is solvable.

1. Water flood is a push-pull operation. You start by assuming there was SOME viscosity left in the oil in the producing horizon. You simply do just that: you flood a chosen well with water, and push the oil out to other wells that would be pumping furiously to help pull the oil in. This has been used very successfully in a failing oil field near Taft, California. To do this, of course, you would have to set cement and screens on your well to allow fluid movement only at the producing horizon, and case (or block out) the other horizons – or you will lose all your water. You also need a substantial supply of water, not something easily found in an arid agricultural region like the southern San Joaquin Valley.

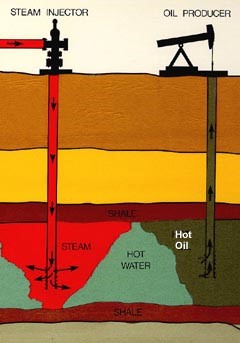

2. With steam flood, something was added to the push-pull: heat designed to lower the viscosity of the gooey stuff. The engineers built huge steam generators in several locations around the Kern Field. These things were monstrous: they looked like huge silver cans lying on their sides – cans the size of a diesel locomotive. The engineers would heat water to 500 degrees F, and pump it at 500 psi down the production pipes for 5 days – the so-called 5/5/5 (and why this part of the story is not metric). They would then let it “stew and cook” for two days, then would un-cap those same production pipes and just let the steam blow off for several days. Then they would start the pumps going again. For a surprisingly long time afterwards, the once-abandoned production wells would easily produce 50 – 300 barrels (8 to 50 cubic meters)/day. There are actually two versions of steam flood: a steady push like fire flood (below) and an episodic version that I’ve just described. This episodic version can work with a single well instead of multiple wells, and is called “Huff and Puff.”

3. With fire flood, the ante (and the risk) was ratcheted up another notch. More wells are needed. After carefully imaging the producing horizon with seismic methods, engineers would drill a circle of wells around a central well. In the central well, you would ignite a fire in the oil at the producing horizon, then push air down into this well at phenomenal rates, up to 900 cfm (cubic feet per minute, or 25 cubic meters per minute). The heat and the pressure would “loosen up” the heavy crude around that starter well, and drive it towards the surrounding peripheral wells. There was one immediate problem: the producing horizon is never quite uniform, which meant that the fire reached one ring-well before the others. To keep this from blowing out explosively, the engineers put thermocouples down each of the peripheral wells. When one got too hot, they would shut down and cap that well, and the firewall would follow the pressure gradient to the other wells instead.

I’ve seen drill core from these Kern Field wells before and after a fire flood passed through them: beforehand the cores looked like cylinders of black, sandy tar. Afterwards, the cores looked like solid white beach sand!

I said earlier that there was a separate problem, and my first introduction to this was startling. An engineer at a fire flood operation gave us a tour of the field. First, he opened a spigot on a pipe and out burbled a tan-colored (and SO2-rotten-egg-smelling) goop into a bucket. We watched it for a moment, and then he led us away to see the huge fans used to drive the air down the central well to keep the combustion going. After an hour or two, he steered us back to the bucket. He asked me to lift it. With difficulty I did. “Turn it over,” he said. Gingerly, using gloves because it was still quite hot, I turned it over.

And nothing poured out. That tan goop had turned solid long before it had dropped back to room temperature. Scratch that bucket.

So, what do you do about this? It turns out that about the only thing you can do – besides adding some very expensive, environmentally-iffy chemicals like they do in the Athabasca Tar-Sands – is to make a slurry of this stuff. Mix the heavy crude with sweet crude from a different nearby field into a solid-liquid slurry, and it would then move down the pipeline to a refinery without clogging that pipeline. A slurry is like Bubble Tea – that sweet Japanese drink with liquid surrounding little balls of semi-solid tapioca. You can easily get it through the straw – but not if the tapioca settles on the bottom!

As you might expect, “cracking” this heavy-crude-light-crude slurry was a lot more complicated than cracking the sweet crude into diesel and gasoline. So… this oil was technically accessible, but more expensive to turn into gasoline.

We thus get back to that old physics conservation law: ain’t no such thing as a free lunch.

There is a newer, more controversial technology called “fracking” (see the later chapter specifically with that name). This is another way to get certain “tight” rock formations – rocks like dark, carbon-rich shale formed in an ancient swamp – to surrender some of that carbon. The problem with “tight” rock is that it has very low porosity, so the oil, while abundant, cannot move around within nor escape it easily, no matter how much you heat it. Think of trying to squeeze water out of a towel… then think of trying to squeeze water out of a piece of leather. It just can’t get out…

Unless you shatter the leather. And that ain’t no free lunch, either.

The next part of this explanation will address yet another example of human ingenuity: It’s titled “The Hubbert Curve – how we cheat it.”

Figure 57. A steam-flood operation to extract heavy crude. Image: United States Dept of Energy – http://fossil.energy.gov/education/energylessons/oil/oil4.html, Image: DOE Public Domain.